Industrial Hose Production Services

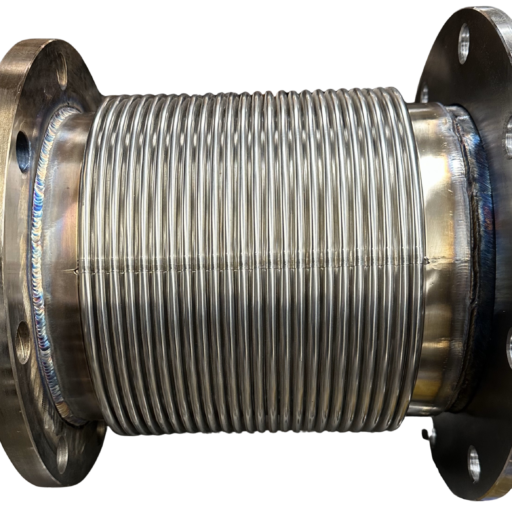

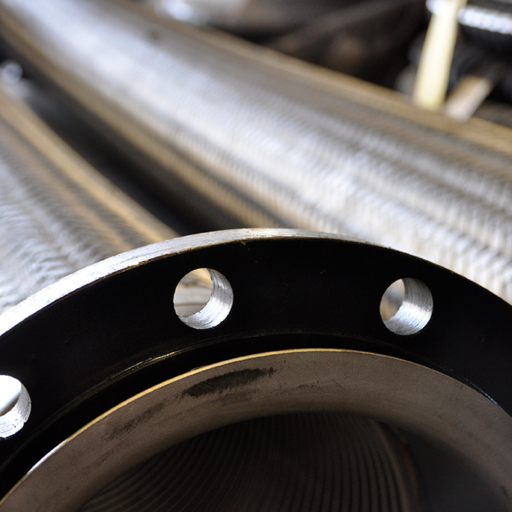

A leader in supplying industrial hoses and hose assemblies in Louisiana, Spartan Industrial ensures hoses are assembled to meet and exceed industry standards. We employ experienced fabricators that meet and exceed industry standards and receive updated best practice training on NAHAD assembly guidelines. We handle both small id and large bore assemblies in a variety of lengths and hose end configurations. Contact our experts today for more information about metal hose and expansion joints.

Why Choose Crimping Over Clamping for Industrial Hoses?

When securing industrial hoses, two primary methods are used: crimping and clamping. While both have their applications, crimping is often the superior choice for many industrial uses due to its reliability, safety, and long-term durability.

Advantages of Crimping Over Clamping:

Stronger & More Secure Connection – Crimping creates a uniform, tight seal around the hose fitting, reducing the risk of leaks, blow-offs, or failures under high pressure.

Increased Safety – Properly crimped hoses are less likely to come loose, preventing accidents in high-pressure environments such as hydraulic systems and industrial fluid transfer.

Better Durability – Crimped connections are more resistant to vibration, temperature fluctuations, and chemical exposure compared to clamped hoses.

Leak Prevention – Unlike clamps, which can loosen over time, crimped fittings provide a permanent and reliable seal, reducing maintenance costs.

Customization & Precision – Crimping allows for consistent, factory-quality connections tailored to specific pressure ratings and hose sizes.

Compliance with Industry Standards – Many industries (e.g., oil & gas, food processing, and chemical transport) require crimped connections to meet safety and performance regulations.

When to Use Clamping Instead of Crimping

Low-pressure applications where occasional adjustments may be needed.

Temporary or emergency repairs.

When the hose assembly does not require strict industry standards for pressure and safety.

FAQs

What is hose crimping?

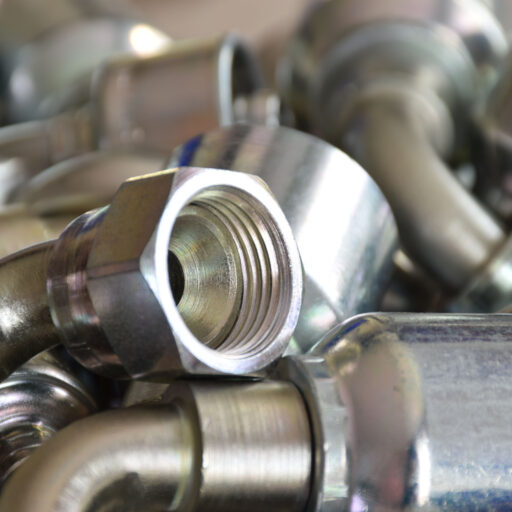

Hose crimping is the process of permanently attaching a fitting to a hose using a crimping machine, which compresses a metal sleeve (ferrule) over the hose and fitting to create a secure and leak-proof seal.

How does crimping compare to traditional hose clamping?

Crimping provides a stronger, more reliable, and permanent connection compared to clamping, which relies on manual tightening and can loosen over time.

What industries require crimped hoses?

Crimping is commonly used in industries such as hydraulics, manufacturing, food and beverage processing, pharmaceuticals, oil and gas, and chemical transport.

Can crimped hoses be reused?

No, crimped hoses are typically a one-time assembly. If a hose needs to be replaced, a new hose and fitting must be crimped.

Do crimped hoses require special equipment?

Yes, crimping requires a hydraulic or pneumatic crimping machine to ensure a precise and secure connection.

What are the risks of using clamped hoses instead of crimped hoses?

Clamped hoses can loosen due to vibration, temperature changes, or pressure fluctuations, increasing the risk of leaks, system failures, and potential safety hazards.

Are crimped hoses more expensive than clamped hoses?

While the initial cost of crimping equipment may be higher, the long-term benefits, including reduced maintenance and increased safety, often outweigh the costs.

Can all hoses be crimped?

Not all hoses are designed for crimping. Some low-pressure hoses may be more suitable for clamping, but most industrial and hydraulic hoses are best secured with crimping.

By choosing crimping over clamping for industrial hoses, businesses can ensure better performance, safety, and compliance with industry standards.