Hose Welding Services

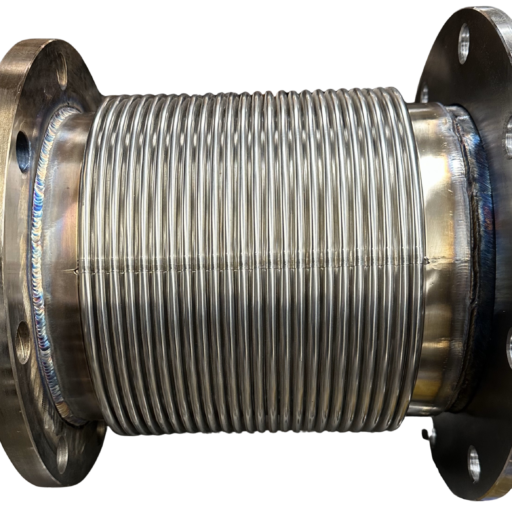

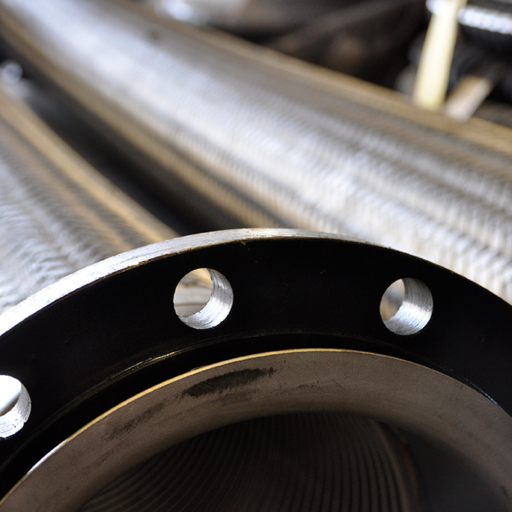

A leader in supplying metal hose and expansion joints in Louisiana, Spartan Industrial ensures hoses are assembled to meet and exceed industry standards. We employ experienced ASME Certified welders to fabricate metal hose and expansion joints to your specifications. We handle both small id and large bore assemblies in a variety of lengths and hose end configurations. Contact our experts today for more information about metal hose and expansion joints.

OEM Metal Hose & Expansion Joints

Original Equipment Manufacturers (OEMs) require metal hoses that meet strict quality, safety, and performance standards. Metal hoses are commonly used in applications requiring flexibility, high-pressure resistance, and durability in extreme environments.

What are the best applications for metal hoses when designing equipment?

Metal hoses are widely used in:

- High-temperature exhaust systems

- Cryogenic fluid transfer

- Hydraulic and pneumatic systems

- Aerospace and automotive applications

- Industrial and chemical processing plants

How do I choose the right metal hose for my OEM application?

Consider the STAMPED method:

Size: Inside diameter (ID), outside diameter (OD), and overall length.

Temperature: Maximum and minimum operating temperatures.

Application: Movement, vibration, pressure, and flexibility needs.

Media: Type of fluid or gas being transported.

Pressure: Working pressure, surge, and burst ratings.

Ends: Fittings and attachment methods.

Delivery: Lead times, compliance, and packaging requirements.

What maintenance is required for metal hoses?

Regular inspections for cracks, leaks, or corrosion.

Ensure proper routing to prevent excessive bending or kinking.

Clean hoses periodically to remove contaminants that could degrade performance.

Replace hoses at recommended intervals to prevent unexpected failures.

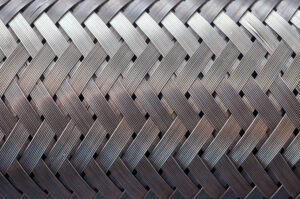

Single or Double Braid Options for Metal Hoses, how do I choose?

When selecting a metal hose do I use Single or Double Braiding

When selecting a metal hose, choosing between single or double braiding depends on the application’s pressure, flexibility, and durability requirements.

Single Braided Hose: Offers flexibility while providing reinforcement against internal pressure. Suitable for moderate-pressure applications where flexibility is a priority.

Double Braided Hose: Provides additional strength and pressure resistance, making it ideal for high-pressure applications or environments with frequent movement and vibration.

FAQs

When should I use a double-braided hose instead of a single-braided one?

A: Use double braiding when your application involves high-pressure fluids or gases or when added durability is required for long service life.

Does double braiding reduce flexibility?

A: Yes, double-braided hoses tend to be less flexible than single-braided ones due to the additional reinforcement. If flexibility is crucial, a single braid may be the better choice.

How does braiding affect pressure ratings?

A: Double-braided hoses can withstand significantly higher pressures compared to single-braided hoses, making them essential for high-pressure industrial applications like steam or hydraulic systems.

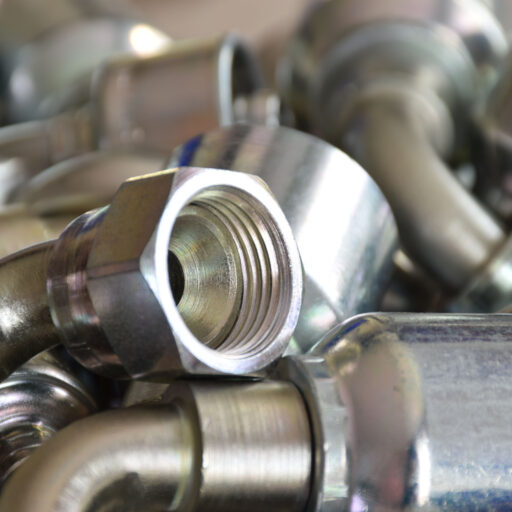

There is a wide variety of fittings to choose from with metal hoses and expansion joints?

What kind of couplings can I have on a Metal Hoses?

Choosing the right metal coupling for a welded metal hose depends on the application, pressure, temperature, and fluid compatibility. Metal hose does provide a unique quality in that you can weld metal couplings along with metal tubing or accessories right on the hose. Common couplings include:

Flanged Couplings – Ideal for easy assembly and disassembly in high-pressure applications.

Threaded (NPT/BSP) Couplings – Used for secure connections in fluid and gas systems.

Hydraulic Couplings Including JIC – Used for high pressure applications and sealing on the mechanical JIC flare.

Cam & Groove Couplings – Quick-connect fittings for rapid attachment and detachment.

Tri-Clamp Couplings – Common in sanitary applications such as food and pharmaceutical industries.

Weld Nipple Couplings – Provide a permanent, high-strength connection for extreme conditions.

FAQs

Which metal coupling is best for high-pressure applications?

A: Flanged or weld nipple couplings are best, as they provide a strong, leak-proof seal.

What type of coupling is best for quick connections?

A: Cam & Groove couplings allow for fast attachment and detachment without tools.

How do I ensure compatibility between the coupling and hose material?

A: Match the coupling material (e.g., stainless steel, carbon steel) with the hose to prevent corrosion and ensure structural integrity.