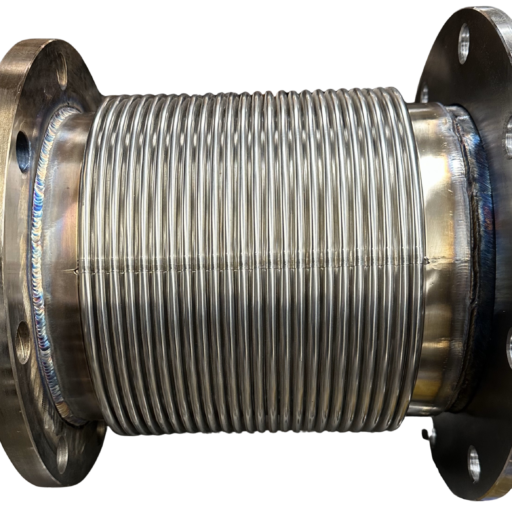

Custom Metal Exhaust Bellows

Spartan Industrial & Marine is the premier choice for custom metal exhaust bellows due to our commitment to quality, durability, and precision engineering. Our bellows are manufactured using high-grade materials designed to withstand extreme temperatures, vibration, and corrosive environments, ensuring long-lasting performance in demanding applications. With decades of industry expertise, we provide tailored solutions that meet the specific requirements of marine, industrial, and exhaust system applications. Our team works closely with customers to design and fabricate bellows that offer superior flexibility, reliability, and efficiency. We maintain a strong inventory and streamlined production processes to deliver quick turnaround times without compromising quality. When you need custom metal exhaust bellows that excel in both performance and longevity, Spartan Industrial & Marine is the trusted partner you can rely on.

Metal Exaust Bellows to your Design

Ideal Applications for Custom Metal Exhaust Bellows:

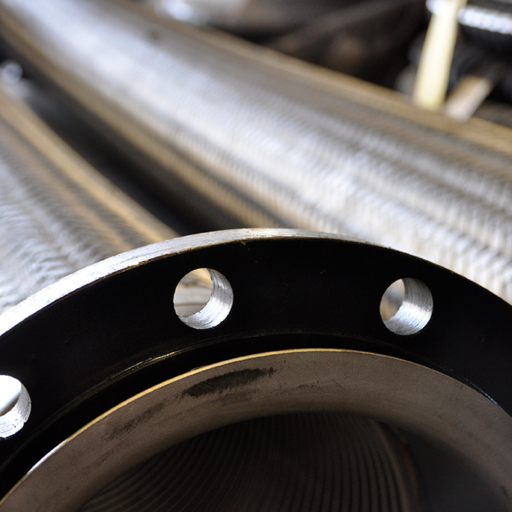

Marine Exhaust Systems – Absorbs vibrations and compensates for movement in ship engine exhaust systems, ensuring reliable performance in harsh marine environments.

Industrial Power Generation – Provides flexibility in exhaust piping for gas turbines, generators, and other heavy-duty power equipment, reducing stress on connected components.

Heavy-Duty Vehicle & Equipment Exhausts – Used in trucks, construction machinery, and off-road vehicles to accommodate thermal expansion and movement, enhancing exhaust system longevity.

6 Common FAQs About Selecting Metal Expansion Joints

What factors should I consider when selecting a metal expansion joint?

When choosing a metal expansion joint, consider factors such as temperature range, pressure rating, movement requirements, media compatibility, and installation environment. These will determine the best material, design, and construction for your specific application.

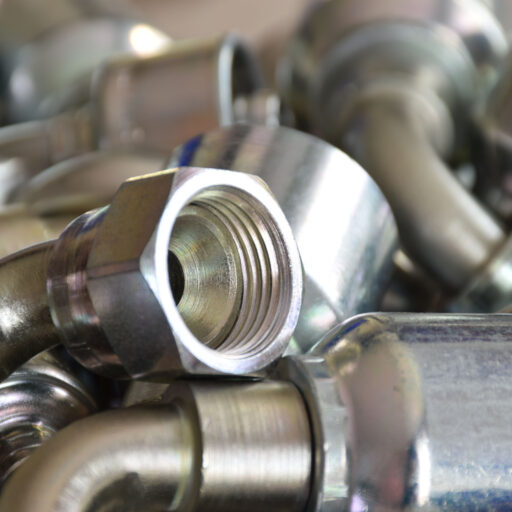

What materials are commonly used for metal expansion joints?

Stainless steel is the most common material due to its strength, corrosion resistance, and ability to handle high temperatures. Depending on the application, other alloys such as Inconel, Hastelloy, or Monel may be used for enhanced durability in extreme conditions.

How do I determine the right size and movement capability for my application?

Expansion joints must be sized according to pipe diameter, movement requirements (axial, lateral, or angular), and the amount of expansion and contraction expected. Proper calculations ensure that the joint can absorb movement while maintaining system integrity.

Do metal expansion joints require maintenance?

While metal expansion joints are designed for durability, regular inspections are necessary to check for signs of fatigue, corrosion, or misalignment. Proper installation and periodic maintenance help extend the life of the joint and prevent system failures.

What are the benefits of using metal expansion joints over rubber or fabric alternatives?

Metal expansion joints can withstand higher temperatures, pressures, and corrosive environments compared to rubber or fabric options. They also offer superior longevity, making them ideal for demanding industrial, marine, and power generation applications.

Can metal expansion joints be customized for specific applications?

Yes, metal expansion joints can be custom-designed to fit specific requirements, including special materials, multi-ply bellows, unique end fittings, and special coatings for added protection. Working with an experienced manufacturer ensures a solution tailored to your system’s needs.”