Choosing the right chemical-resistant hose is essential for maintaining safety, efficiency, and durability in industrial operations. The right hose should withstand exposure to harsh chemicals, extreme temperatures, and varying pressures without degrading or failing. Below, we’ll walk you through the key factors to consider, common selection mistakes, and best practices for extending the lifespan of your hoses.

Key Factors in Choosing a Chemical-Resistant Hose

When selecting a hose for chemical applications, ask yourself:

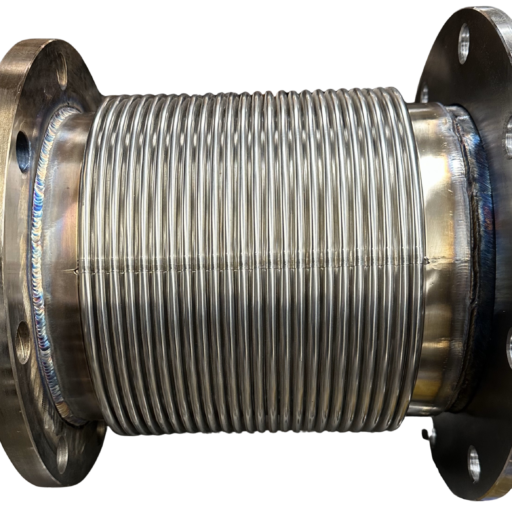

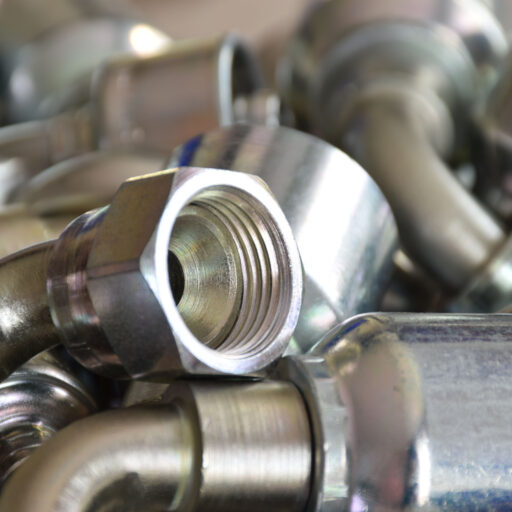

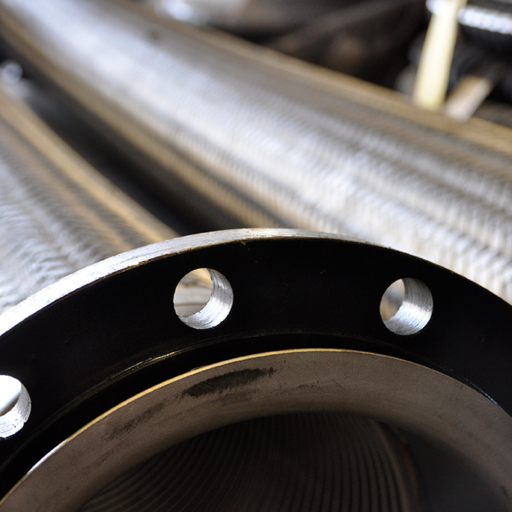

- Is the material compatible with the chemicals being transported? Options like PTFE, rubber, stainless steel, and composite hoses each have different resistance levels. Always check compatibility charts.

- Can the hose handle temperature extremes? High temperatures can weaken hoses and lower their pressure rating—so check derating charts.

- Does the pressure rating meet system requirements? A hose must be able to handle both operating and burst pressures safely.

- Is flexibility important? Some applications require tight bends, but exceeding the hose’s minimum bend radius can cause premature failure.

- What about conductivity? If static buildup is a concern, choose a conductive hose and ensure proper grounding to fittings.

- Does the size and length match your system? Using the wrong hose size can lead to inefficiencies and potential safety risks.

Common Mistakes to Avoid

- Ignoring Chemical Compatibility – Not all hoses can handle all chemicals. Always verify compatibility before purchase.

- Overlooking Temperature Limits – A hose that can’t handle extreme temperatures will degrade faster and might have a reduced pressure rating.

- Selecting the Wrong Pressure Rating – A hose with an inadequate pressure rating could rupture, creating hazardous conditions.

- Neglecting Regular Inspections – Routine maintenance helps detect wear, leaks, or degradation before failures occur. Our OnGuard™ hose management system helps keep track of hose conditions for enhanced safety and longevity.

How to Extend the Lifespan of a Chemical Hose

✔ Conduct Regular Inspections – Check for cracks, bulges, and leaks.

✔ Store Hoses Properly – Keep them in a cool, dry area away from UV rays and harsh chemicals.

✔ Ensure Correct Installation – Avoid excessive bending, twisting, or improper routing.

✔ Flush & Clean Regularly – Prevent chemical buildup and contamination with proper cleaning protocols.

Need Help Selecting the Right Hose?

Choosing the correct chemical-resistant hose is crucial for workplace safety and operational efficiency. If you need expert guidance, contact our team today for tailored recommendations.